TYPES OF KNIFE MILLING

Minggu, 29 Maret 2015

Tambah Komentar

Cutter, milling machines exist in several shapes and sizes. There is also an option that has a coating, as well as the angular waster furious and cut the number of the lot.

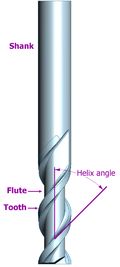

In general, a blade milling has the following parts:

In general, a blade milling has the following parts:

|

| blade section frais |

- Shape: The shape of the blade milling Several standards are used in the industry today, which is described in more detail below.

- Flute / Flow / Total gear: Flute in the picture above is a helical groove along the blade milling, while the sharp knife along the edge known as tooth. Teeth cut material, and grams of this material are attracted to the groove by the rotation of the blades. Almost always there is one tooth per flute, but some cutters have two teeth per flute. Milling knife may have one to many teeth, with 2, 3 and 4 are the most common. Typically, the more the number of teeth faster cutting process the material. Thus, 4-tooth cutter can Meakan material at twice the rate of 2-tooth blade.

- Helix angel / Helix Angle: Chronology of the milling cutter blade is almost always helix. If the plot is straight, the whole tooth will impact material feeds at once / unison, causing vibration and reduces accuracy and surface quality. Typically, finishing cutter has a higher rake angle (tight helix) to provide a better end result.

- Center cuts: Some blade milling can mememakan straight down (translucent) through the material, while others can not. This is because some of the cutting teeth do not have a slope to the center of the flashlight. The knife can cut down at an angle of 45 degrees or more.

- Roughing / Ingestion Rough or Finishing: Various types of cutters there are available for large funeral / rough, leaving a poor surface finish, or for burial bit, but leaving a good surface finish (finishing).

- Coating / Coating: Coating the right tools can have a great influence on the cutting process by increasing cutting speed and life / service life, and improve the smoothness of the surface finish. Polycrystalline Diamond (PCD) is a very hard coating used on the cutter must withstand high abrasive wear. A PCD coated tool can last up to 100 times longer than uncoated tools. However layer can not be used at temperatures above 600 degrees C, or on ferrous metals. Tools for aluminum engines are sometimes given a layer of TiAlN. Aluminum is a metal that is relatively sticky, sticky and can itself into gear tool, causing them dull. But it is likely to not stick TiAlN, which allows the tool to be used longer in aluminum.

- Shank: cylindrical shank is not grooved part of the tools used to hold to the vise. Sometimes a diameter that may be different than the inner diameter of the cutting tool, so it can be held by a standard tool holders.

Knife Type Milling

|

Slot (top), Ball nose end mill and mill

Blade slot (top row in the picture) is a type of endmills with center cutter. Generally have a two (sometimes three or four-) groove cutter is capable of performing drilling (cutting through) straight down into the material and then moves laterally to cut the slot.

Roughing Endmill

The blades are rapidly consuming large amounts of material. This type uses a form of wavy cut teeth on the edges. Wavy teeth forming sharp edges successively producing many small chips, resulting in a relatively rough surface finish. During cutting, some teeth are in contact with the workpiece reduce noisy and vibration.

HPMT mill

Ball nose cutter (bottom in the picture above, yes it's funny ....) is similar to drill slot, but the cutter tip is hemispherical. They are ideal for machine 3-dimensional contoured shape in the center of the machine, for example in the mold and die. They are also used to increase the radius of the surface perpendicular to reduce stress concentration / friction.

Roughing Endmill

The blades are rapidly consuming large amounts of material. This type uses a form of wavy cut teeth on the edges. Wavy teeth forming sharp edges successively producing many small chips, resulting in a relatively rough surface finish. During cutting, some teeth are in contact with the workpiece reduce noisy and vibration.

HPMT mill

Ball nose cutter (bottom in the picture above, yes it's funny ....) is similar to drill slot, but the cutter tip is hemispherical. They are ideal for machine 3-dimensional contoured shape in the center of the machine, for example in the mold and die. They are also used to increase the radius of the surface perpendicular to reduce stress concentration / friction.

Slab Mill

|

| slab mill |

Blade surface and Side

|

| blade surface and sides |

Side surface of the cutting blade and is designed with the teeth on the sides as well as the circle. They are made in a variety of diameters and widths depending on the application. Teeth in addition allows the cutter to make cuts unbalanced (cut on one side only) without deflecting cutter as would happen with cutting saws that no side teeth.

Spiral tooth cutter / involute gear cutter

Spiral tooth cutter / involute gear cutter

|

| Involute gear cutter |

Above is an example that is a spiral-shaped cutter teeth - number 4:

· Pitch diameter cutter 10

· Pieces gear from 26 to 34 teeth

· 14.5-degree pressure angle

Hobbing

|

| hobing mill |

The cutter is a kind of tool used in forming and hobbing machines to produce gears. A cross-section cutting teeth will produce the required shape on the workpiece, once arranged for appropriate conditions (empty size). A hobbing machine is a special milling machine.

Knives Frais Surface / Face mill

Knives Frais Surface / Face mill

|

| Carbide Facemill |

A face mill consists of a few side pieces are designed to withstand the carbide tip. Tips are not designed to be resharpened / honed back and selected from various types which can be determined by a variety of criteria, some of which may be: shape of the tip, the actions required, the material being cut. When tips are blunt, they can be removed, rotated (indexed) and substituted for surface sharp knife to the workpiece, this increases the life of the blade.

Belum ada Komentar untuk "TYPES OF KNIFE MILLING"

Posting Komentar

Terima kasih sudah mampir dan membaca blog saya, jika berkenan silahkan tinggalkan komentar