TYPES OF MATERIAL FOR MACHINE

Jumat, 27 Februari 2015

Tambah Komentar

Type of Material

There are many different types of materials to choose from when doing a project. For purposes of our discussion, the basic ingredients are grouped into two categories, to be "non-metallic" and metal. In regard to this metal material, is then further divided into two groups: "ferrous" and "non-ferrous". Each of these materials have their own characteristics and require different mechanical engineering. Careful consideration needs to be given to the selection of the correct material for aplikasi.Ferrous means it contains iron, steel for example. Non-ferrous Metal instance does not contain aluminum, copper and others. A simple test for ferrous materials / non-ferrous is to use magnets as examiners, of course, the iron will be attracted by a magnet.

The following are common materials used in the lathe:

Aluminum Alloy (aluminum alloy)

There are many types of metal alloys to choose from, but Aluminum is often chosen because it is lightweight (approximately 2700 kg / m3 density), it is relatively soft and easily processed properly. From the point of view of machine technique, pure aluminum (JIS A1000) is very different from the Al-Cu alloys (JIS A2000).

Pure aluminum is easy to bend but difficult to process because it is too soft and easily clog cutlery. On the other hand, Al-Cu alloys, such as A2017 or A2011 (called duralumin) is easy to turner and cut, but with some values have powers similar to baja.Salah one disadvantage of aluminum is that it is difficult to weld or soldered.

Is very difficult to distinguish between pure aluminum, Al-Cu alloys and etc. When they are cut by machine, we can recognize from the process of turning the material.

Figure 1, Aluminum Alloy (JIS A2017)

Stainless steel

Stain-less-steel (steel not stained), according to the Japan Industrial Standard JIS SUS304 specs are. Indonesia is a common term in Stainless steel 3% and 8%. The percentage in question is the nickel content.

The benefits of stainless steel is that it has a high strength, heat resistance high enough, and and stainless. Due to its high resistance to heat that makes it an ideal material for mechanical parts that undergo heating. Also, because the material resistance to rusting, is ideal for use on the machine is exposed to water. Other examples of its use in the drive shaft ship where both strength and corrosion resistance is required.

Stainless Steel tends to be a bit sticky when done on a lathe and because this means also is material relative tends to shorten the life of cutting tools used, such as lathe chisel or drill bit. The cutting tools need to be sharpened frequently, especially in turning operations that much. Stainless steel can usually be identified with a shiny silver color.

Fig.2, Stainless Steel (JIS SUS304)

Carbon steel

Specifications carbon material according to the Japanese Industrial Standard JIS S45C is and JIS SS400. They are relatively inexpensive, easy to weld, and they can experience a variety of heat treatments. Because many machine tools designed for cutting mild steel material, it is rare to face problems when done on a lathe.

Often also called common steel or common steel. ST60 example.

I am almost every day using this steel, in addition to commonly used, also because it is cheaper and easier processing.

Generally, this steel has a black surface and the surface is very difficult to be separated, if possible, the surface should be left intact because it offers additional protection.

Fig.3, Carbon Steel (JIS S45C)

Brass

Brass is an alloy made from a combination of copper and zinc as the main ingredient. In comparison with carbon steel or stainless steel, brass machine capabilities of both, and also have good soldering properties.

Brass is very heavy because of the high density so it is ideal for heavy parts, such as the flywheel or the weight balance for the machine model.

Brass is very expensive when compared with other materials that are used very selectively.

Fig.4, Brass (JIS C2800)

Identification of the material

Typically, billet or axles of the material sold in lengths of 6 meters (or less).

But in everyday life, many grocery stores that sell at retail.

Usually the material in the form of written material as carry identification at the end as seen in the photo at the bottom.

Fig.5, Indications Materials

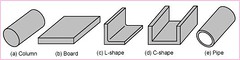

The general form

Material is usually given as a general form and it is

(A) Billet (as / round-bar),

(B) flat bar (plate),

(C) Elbow (L-shaped),

(D) channel "U"

(E) the pipe.

The selection of the right materials helps in simplifying the project.

Fig.6, Forms General Materials

Size axles / Roundbar Common in lathe

Size as common are: 1/2 ", 5/8", 3/4 ", 7/8", 1 ", 30mm, 32mm, 40mm, 50mm, 60mm and 80mm (Yet another size can be ordered).

Belum ada Komentar untuk "TYPES OF MATERIAL FOR MACHINE"

Posting Komentar

Terima kasih sudah mampir dan membaca blog saya, jika berkenan silahkan tinggalkan komentar